- +91-98141-21288

- Opp. B.N Duggal Petrol Pump, G.T. Road, Phagwara 144401 Punjab, INDIA

- Mon-Sat: 8.30 AM - 5 PM

Pneumatic Grease Pumps

Pneumatic Grease Pumps

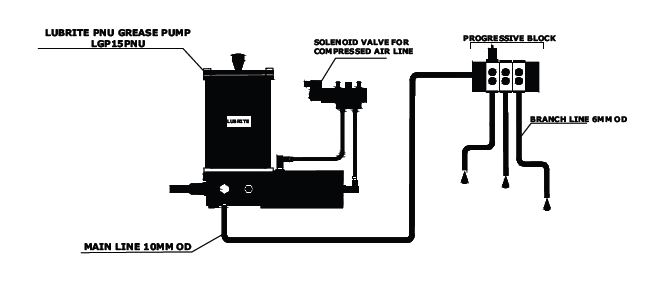

Lubrite's Pneumatic Grease Pumps are integrated with a pneumatic cylinder and operate via pneumatic lines connected to the cylinder ports through a manual or electrical Direction Control Valve (DCV). During the forward stroke, grease is dispensed under pneumatic pressure through the pump's outlet port. In the reverse stroke, grease is drawn into the pump body through the suction port, ensuring continuous operation.

These pumps are designed for wall mounting and must be installed vertically at a location easily accessible to the operator. A bleed valve is provided on the pump body to release trapped air in the system. Before operation, the bleed valve should remain open until a consistent flow of grease is observed.

A telltale rod extending through the container top provides a clear indication of the remaining grease level at any time. To maintain optimal performance and prevent contamination, a filter and regulator unit should be installed in the pneumatic lines to ensure the air supply is free from dust and moisture.

Technical Specification

| Specification | LGP. Pn. 15 |

|---|---|

| Reservoir Capacity | 1.5 kg |

| Discharge Per Stroke | 1.5 gm |

| Maximum Pressure | 50 kg/ sq.cm. |

| Input Pneumatic Pressure | 4-6 kg/ sq.cm |

| Minimum Frequency of Operation | 1 minute |

| Overall Dimension | 320X120X425 MM |

| Mounting Details | 90 MM |

* Recommended Grease NLGI 00, 0, 1 & 2