- +91-98141-21288

- Opp. B.N Duggal Petrol Pump, G.T. Road, Phagwara 144401 Punjab, INDIA

- Mon-Sat: 8.30 AM - 5 PM

Metering Cartiridges

Metering Cartiridges

In the Single Shot Centralized Lubrication System, the amount of oil at each lubrication point is controlled by the element known as Metering Cartridge. For each lubrication point, at least one metering cartridge has to be used. The metering cartridges are Metering Valves where a stroke of the Piston determines the amount of oil to be ejected. The Cartridges operate as soon as pressure builds up in the lubrication line. When the pump is off and the pressure in the lubrication line drops, Cartridges get recharged for the next cycle. A small-time gap (minimum 1 minute) is allowed between the subsequent operations of the Pump for proper recharging of the Metering Cartridges.

Discharge Range

| MC 1 | MC 2 | MC 3 |

|---|---|---|

| 0.03 cc (1 drop) | 0.25 cc (8drop) | 1.00 cc(30 drop) |

| 0.05 cc (2 drop) | 0.40 cc(12 drops) | 1.60 cc(50 drop) |

| 0.10 cc (3 drop) | - | - |

| 0.16 cc (5 drop) | - | - |

Dose Selection

Dose of metering cartridge to a particular points shall be determined as per following procedure.

1. Calculate equivalent areas as below :

a) PLAIN BEARINGS

- A = DL

- D = Shaft Diameter

- L = Length of Bearing

b) GEARS

- A = D x W

- D = Pitch Diameter of gear

- W = width of Gear

c) LARGE BULL GEAR

- A = 2 D x W

- D = Pitch Diameter of Pinion

- W = Width of Gear

d) WORM GEARS

- A = (D1 + D@) W

- D1 = Pitch diameter of worm

- D2 = Pitch Diameter of Worm Gear

- W = Width of Worm Gear

2. Select metering Cartridge as per the following table :

| Area to be Lubricated in Cm Sq | Dose in cc |

|---|---|

| Upto 12 | 0.03 |

| 12 to 20 | 0.05 |

| 20 to 40 | 0.10 |

| 40 to 65 | 0.16 |

| 65 to 100 | 0.25 |

| 100 to 150 | 0.40 |

| 150 to 400 | 1.00 |

| 400 to 650 | 1.60 |

3. This dose is normally sufficient for every hour. it is to be noted that following factors may effrct the volume required.

a) Shock Loading

b) Extreme heat

c) High Speed

d) Dusty Atmosphere

Volume can be increased by selecting metering cartridges of higher dose or increasing the frequency of lubrication Cycle.

4. For Metering Cartridges of dose other than above mentioned consult us.

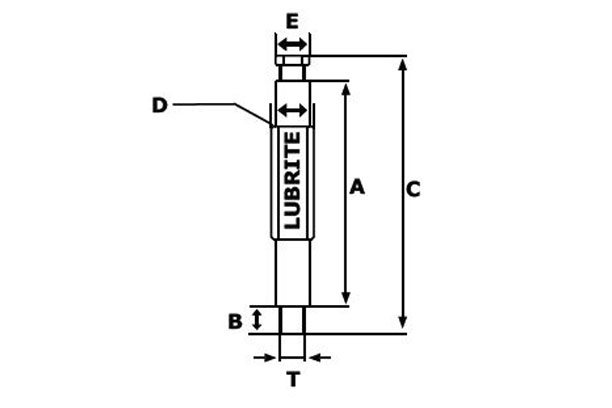

| Model | Dimensions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | T | ||||||

| MC-1 | 37 | 7 | 50 | A/F 11 | A/F 9 | M8X1 | |||||

| MC-2 | 45 | 7 | 58 | A/F 11 | A/F 9 | M8X1 | |||||

| MC-3 | 64 | 9 | 80 | A/F 18 | A/F 9 | M10X1 | |||||