- +91-98141-21288

- Opp. B.N Duggal Petrol Pump, G.T. Road, Phagwara 144401 Punjab, INDIA

- Mon-Sat: 8.30 AM - 5 PM

Col Systems

Col Systems

COL (Continous Oil Lubrication) System is meant to lubricate bearings of Driers in the front/back side of Paper Machine, Gear boxes of rolling mills and any type of machinery where oil should be circulated continuously. The COL generally consists of stand by Geared Pumps, Duplex Filters, Heat Exchanger & necessary instruments such as Pressure Switch, Differential Pressure Switch, Thermometer Pressure Gauges etc to monitor the working of the system. Oil is lubricated to each bearing with the networking of Pipe lines & Fittings. Inline Filters & Heat Exchanger cleans as well as cools the oil before its enters the bearing housing. The same oil is then ejected from bearing housing to the COL tank through turn header.

Models Available

COL 50, COL 100, COL 200 & COL 300

Models Available

LRU 15, LRU 35 & LRU 63

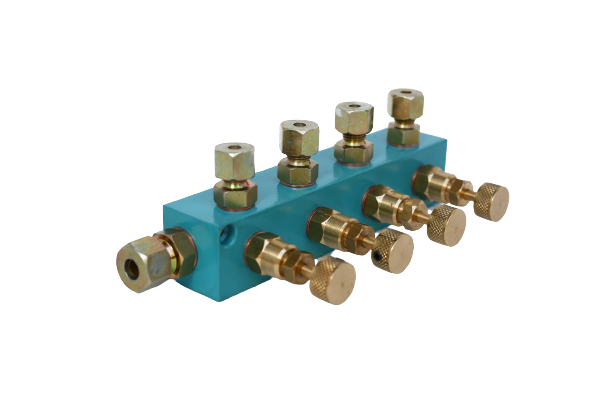

Rotometer (Oil Flow Meter)

Rotameters are installed on the Paper Machine, Gear boxes of rolling mills and any type of machinery where oil should be circulated continuously to regulate the flow of oil in each lubrication point. It is the most essential part of the COL system as the performance of the complete system depends on the rotameters. It consists of adjustable throttle value, Float Indicator & Float Assembly. As the flow indicator is made of polycarbonate, the flow rate can be easily visualized with the movement of the float. Rotameters are available in different flow range as per requirement. Electric sensing can also be provided if required.